InfinitPipe® is a revolutionary technology that allows construction of an endless Fiber Reinforced Polymer (FRP) pipe on-site using the sandwich construction technique. The pipe is made with various layers of resinsaturated carbon or glass fabric that are wrapped around a mandrel and heat-cured. A spacer sheet is used to provide rigidity while reducing the pipe weight to as little as 10% of conventional pipes. The technology has received the 2016 Innovation Award from the American Society of Civil Engineers (ASCE) as the world’s first green and sustainable pipe.

Most pipes manufactured to date require extensive heavy equipment that necessitates manufacturing in a plant. The pipe sections are typically made in 20-feet (7-meter) long pieces and are shipped to the job-site for assembly in the field. This adds significant transportation and installation costs. Worst of all, joints are the weakest link in the pipe where water, gas or oil can leak and cause environmental damage. For sewer pipes, these joints become a source of penetration of roots and a constant maintenance expense.

Most pipes manufactured to date require extensive heavy equipment that necessitates manufacturing in a plant. The pipe sections are typically made in 20-feet (7-meter) long pieces and are shipped to the job-site for assembly in the field. This adds significant transportation and installation costs. Worst of all, joints are the weakest link in the pipe where water, gas or oil can leak and cause environmental damage. For sewer pipes, these joints become a source of penetration of roots and a constant maintenance expense.

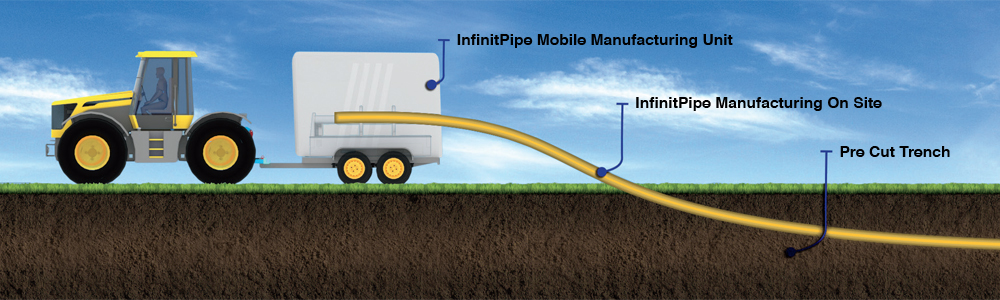

The revolutionary InfinitPipe™ overcomes all of these limitations. The pipe is manufactured on-site by raw materials that are very lightweight and compact and can be shipped in ordinary containers. The construction of InfinitPipe™ starts with a mandrel that has the same shape and size as the pipe being manufactured. Various layers of Carbon FRP and spacer products are wrapped in the field around the mandrel. The number of layers of Carbon FRP is designed based on the required internal pressure of the pipe. The spacer is what gives the pipe its overall stiffness and rigidity. The outer skin of the pipe is wrapped with layers of Glass or Carbon FRP for environmental protection.

Much like the construction of a steel I-beam, this innovative pipe takes advantage of this long-recognized engineering principle and uses an inexpensive light-weight core as the web, while the more expensive carbon fabric is used for the skin only. The epoxy resin is cured in a short time and the pipe is partially slipped off the mandrel; additional lengths of pipe will be made in a continuous manner with no joints — resulting in an infinitely long pipe!

Much like the construction of a steel I-beam, this innovative pipe takes advantage of this long-recognized engineering principle and uses an inexpensive light-weight core as the web, while the more expensive carbon fabric is used for the skin only. The epoxy resin is cured in a short time and the pipe is partially slipped off the mandrel; additional lengths of pipe will be made in a continuous manner with no joints — resulting in an infinitely long pipe!

INFINITPIPE® CAN BE USED TO CONSTRUCT NEW PIPELINES OF ANY LENGTH AND WITHOUT JOINTS TO DELIVER WATER AND OTHER UTILITIES IN DEVELOPING NATIONS.

INFINITPIPE® FEATURES

- New pipeline construction in any environment including developing nations

- Slip-lining pipelines and culverts

- Repair of subsea pipelines

- Water and sewer pipes

- Oil and gas pipelines

- Conduit for housing cables and other utilities

INFINITPIPE® BENEFITS

- Built on-site to any length

- Fewer joints and less pipeline leakage

- Designed for specific project conditions and requirements

- Non-metallic, does not corrode

- Ease of handling; InfinitPipe weighs 10% of conventional pipes

- Sustainable green technology

- Eliminates trucking of pipe segments from factory to jobsite