CARMEL CORROSION

HOW THE WRAP IS CONSTRUCTED AND HOW IT WORKS

CCS wrap is a corrosion protection system designed to be retrofitted to risers, sub sea pipelines, jetty piles and the like in various marine conditions.

CCS HD Wrap, is designed mainly for regular offshore installations whilst the Double Ply is designed for extra durability where needed, i.e. deep-sea structures or where there is a higher occurrence of floating debris or ice floats.

The wrap system is comprised of a memory enhanced polyamid reinforcing scrim, embedded in UV stable polyurethane, to this a polyester felt liner is laminated. Active corrosion inhibitors or biocides are pre-blended into a range of hydrophobic and thixotropic gels. These gels are factory-applied to the absorbent felt inner layer.

The edges of the wrap are fitted with a sophisticated flange enabling fast assembly on site and an excellent watertight seal. The system is delivered as one piece requiring only minimal surface preparation before installation.

When assembled, the polyurethane scrim combination provides hoop tension creating close association between the corrosion inhibiting gel and the substrate.

CLICK HERE TO READ MORE:

CORROSION CONTROL WITH INDUCED TENSION POLYMER WRAPS

BENEFITS

+ Only a minimal amount of surface preparation is required i.e. Marine growth, flaking paint and iron oxide removal by scraping. The combined wrap system allows for adequate flexibility which combined with the corrosion inhibiting gel flow, is capable of adapting to substrate irregularities.

+ Polyurethane impermeability with hoop tension and hydrophobic and thixotropic gel combine to create a watertight barrier preventing oxygenated water from reaching the substrate. This combination also enables installation to submerged structures.

+ Induced hoop tension ensures no extra device or procedure is required for fixing or holding wrap in place and is also sufficient for installation of corrosion monitoring solutions such as weight loss coupons or remote monitoring systems.

+ Unique flange provides watertight seal. A quick and simple assembly does not requiring special skill workforce.

+ Simple removal and refitting procedures, enables regular substrate monitoring and repair.

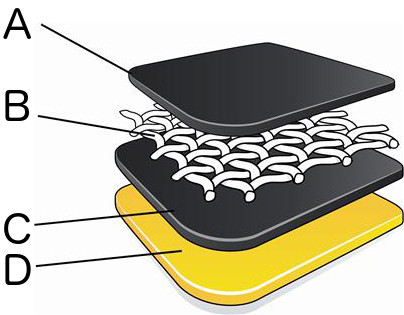

THE STRUCTURE

- A: OUTER POLYURETHANE LAYER

Highly abrasion-resistant and UV-stable.

Long-term environmental outer barrier. - B: MEMORY-ENHANCED POLYAMIDE REINFORCING SCRIM

During installation, these scrims create hoop-tension forces sufficient to resist long-term creep. - C: INNER POLYURETHANE LAYER

- D: POLYESTER FELT INNER LAYER

Active corrosion inhibitors or biocides are pre-blended into a range of hydrophobic and thixotropic gels. These gels are factory-applied to the absorbent felt inner layer in concentrations providing product longevity.

CLICK THE LINKS BELOW FOR MORE INFORMATION